How They Work

realAx peristaltic pump – Strong but gentle

A peristaltic pump works by pressure and displacement. It is used mainly to pump liquids, yet even with solids, through a hose or tube. This is the major difference and design advantage compared to other pump types where parts of the pump actually come into a direct contact with the pumped liquid. This is the reason why peristaltic pumps are so popular and widely used in applications where sterile fluids are required such as medical, pharmaceutical and food and beverage.

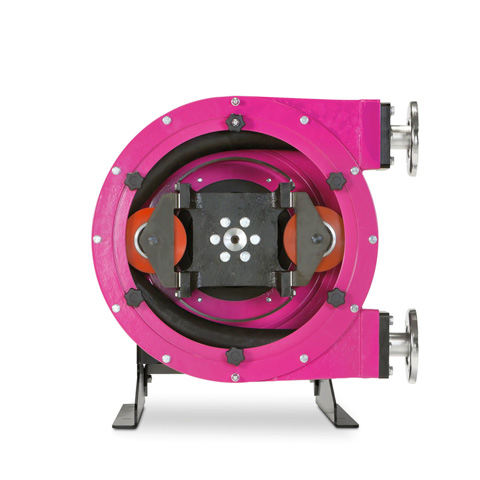

Peristaltic pump operates by allowing fluids into a hose and/or tube. The fluid then flows into the pump casing through the hose / tube. Once there, a rotor with a number of rollers or shoes compresses the hose / tube forcing the liquid on through the pump and directing it to its final destination. The fluid is contained within a flexible hose / tube fitted inside a circular pump casing. As the rotor turns, the part of tube under compression is pinched closed thus forcing the fluid to be pumped to move through the hose / tube. Additionally, as the hose / tube opens to its natural state after passing of the roller or shoe the fluid flow is induced to the pump. This principle is known as peristalsis. Thus, the tool is called a peristaltic pump.

Realax range of hose and tube pumps use either rollers or shoes. There will be two rollers or two shoes occluding the hose / tube. Realax peristaltic pumps can run dry without damage, continuously and can easily reverse rotation. By definition these pumps are corrosion and abrasion resistant and provide high dosing accuracy.

Realax peristaltic pumps are typically used to pump sterile and / or abrasive or aggressive fluids because cross contamination with exposed pump components cannot occur. Some common applications include pumping of aggressive chemicals, high solids slurries and other materials where isolation of the product from the environment, and the environment from the product, is critical. Realax pumps are also suitable to pump shear sensitive liquids because the shear in the pump is as low as <150 s-1.

The operating principle

In essence, a peristaltic hose pump is a type of positive displacement pump. The simplicity of its design provides a number of advantages over other technologies. The hose, which can be made from any of a variety of materials, is housed in the pump body. The pump rotor exerts pressure as it rotates on a set of rollers or shoes which, in turn, compress the hose. This forms a vacuum behind the roller or shoe drawing fluid into the hose while the next roller or shoe gently pushes the fluid forward through the hose. Pump wear is concentrated on the hose component which is quick and inexpensive to replace.

Rollers or shoe

Rollers

Rollers mounted on bearings compress the hose. Less friction and mechanical stress is produced and pressures of up to 8 bar can be supported.

Shoe

The shoe option is preferred for higher operating pressures (up to 22 bar) but it can also create more frictional heat than the roller design.